Aerospace Standard Fitting: AS5202

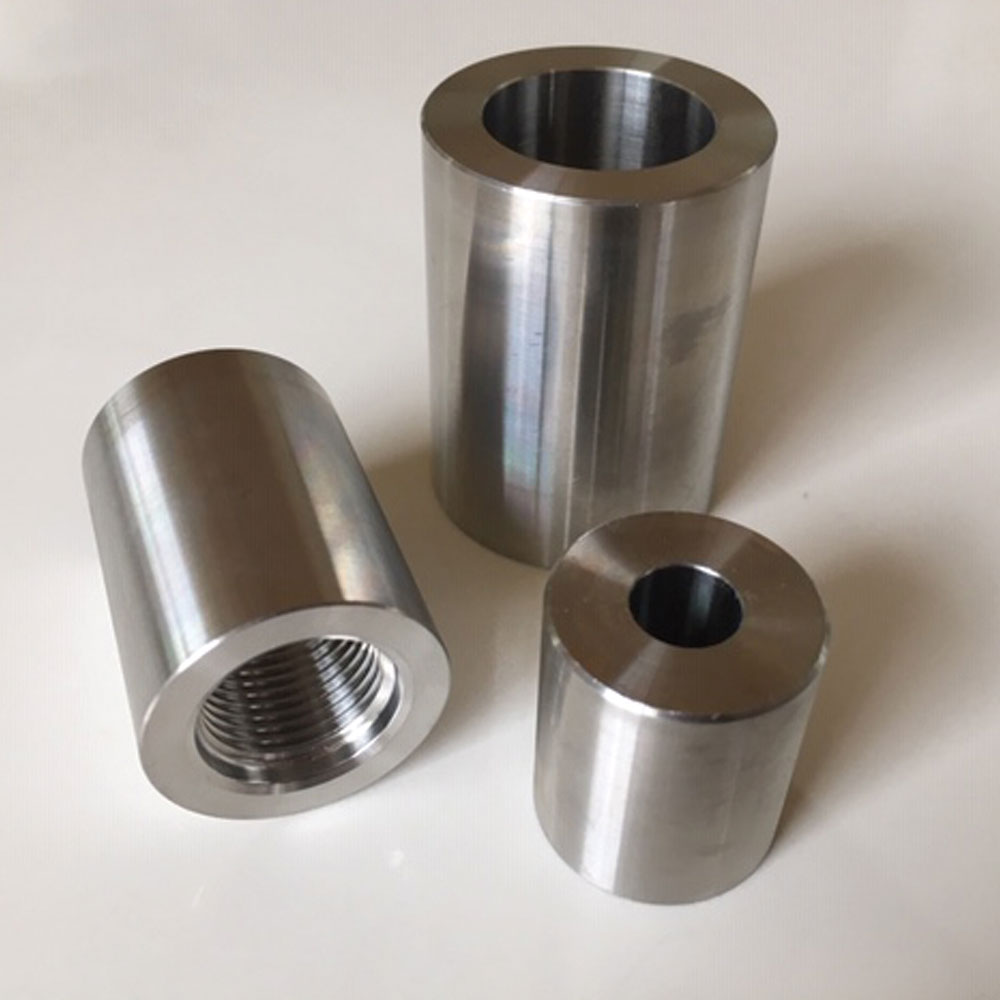

AS5202 WELDABLE PORTIdeal for piping applications. Accepts AS930 type fittings and AS4350 plugs. MS33649 equivalent. Available in a variety of materials. Available in butt, tapered, or socket ends. Diameters and lengths can be customized.

All Fittings

Fittings, fittings, and fittings. Hydraulic and pneumatic fittings. To AS and MS standards or customized per your requirements. For aerospace, piping, drilling and marine applications. In stainless steel and aluminum. AS5202, AS930, AS4350, AS4375, AS4395, AS33514 plus many more.

AS5202 WELDABLE PORT

Weldable boss port with AS8879 or Mil-S-8879 "J' threads. Accepts AS930 straight thread fittings.

Fitting Details

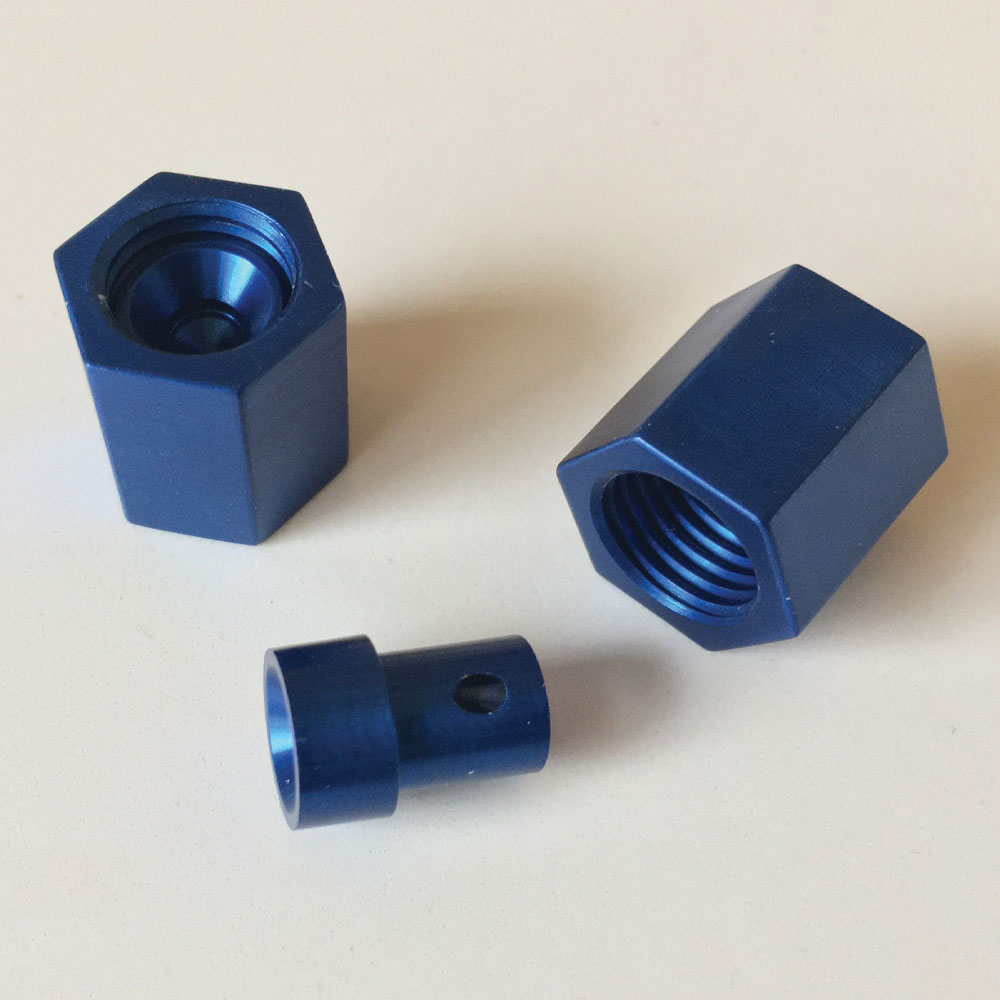

AS4350 HEX HEAD PLUG

Plug for AS5202 and MS33649 ports. Utilizes AS4320 straight thread fitting design. Seals with boss O-ring.

Fitting Details

VWBFPT Adapters AS930 to FNPT

VWBFPT adapters thread into AS5202 and MS33649 ports and accept male NPT fittings. Supplied with AS568-9xx series Buna-N boss O-rings for sealing.

Fitting Details

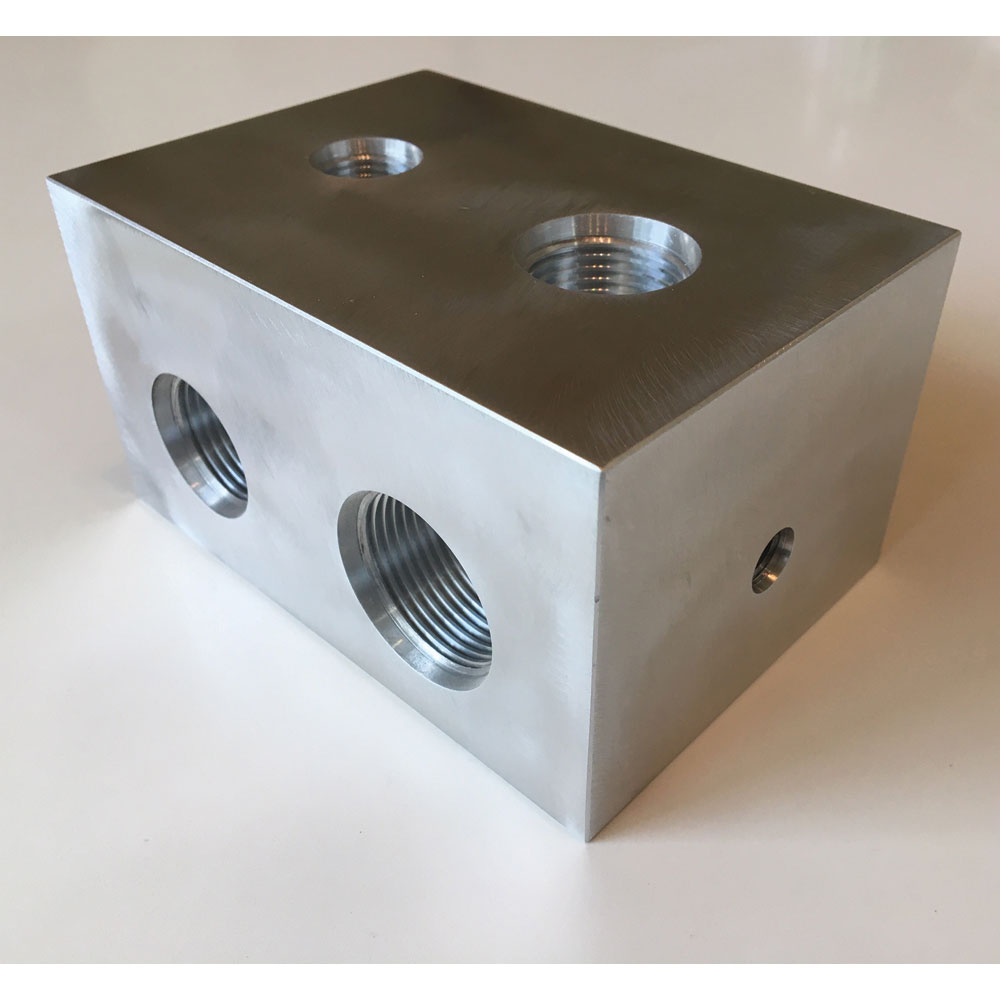

AS5202 MANIFOLD

Manifolds featuring AS5202 ports. Available with identically sized ports or a variety of port sizes. Can also include NPT ports for easy test stand connections. Typically from 304 SS, 316 SS, or Al 6061.

AS931 BOSS PORT CONNECTION TO FLARELESS TUBING ADAPTER

AS930 straight thread fitting on one end mates with an AS5202 boss port while opposite end provides AS4375 or AS33514 flareless connection.

AS934 BOSS PORT CONNECTION TO FLARED TUBING ADAPTER

AS930 straight thread fitting on one end mates with an AS5202 boss port while opposite end provides AS4395 connection for 37 degree flared tubing.

AS1001 FLARELESS BULKHEAD TEE WITH BOSS PORT ON SIDE

Tee consisting of two flareless fittings on the run... one per AS4377 and one per AS4375... plus an AS5202 port on the side.

AS1037 FLARED BULKHEAD UNION

Union for bulkhead consisting of an AS4396 flared fitting on one end and an AS4395 flared fitting on the other end.

AS4329 FLARED CAP ASSEMBLY

Cap AS4395 flared fittings. Available in alternate design featuring safety lanyard.

AS4375 (AS5230) FLARELESS UNION AND REDUCER

AS4375 flareless fittings available in unions (fitting ends of identical size) and reducers (fitting ends of different sizes) per AS5230.

AS4395 (AS5174) FLARED UNION REDUCER

AS4395 flared fittings available in unions (fitting ends of identical size) and reducers (fitting ends of different sizes) per AS5174.

AS5233 FLARELESS CAP ASSEMBLY

Cap AS4375 or AS33514 flareless fittings.

Verus Works

Manufacturer of Aerospace Standard Fitting AS5202Verus Works manufactures hydraulic fittings per aerospace standards published by SAE. Verus Works' most common fitting is an aerospace standard boss port per AS5202 or MS33649. The company's AS4350 hex head plugs or AS5169 bleeder plugs mate with the AS5202 boss ports using the AS930 straight thread port connection design.

Verus Works also offers 37 degree flared fittings based on the AS4395 standard and 24 degree flareless fittings based on the AS4375 or AS33514 standard. The company willingly customizes its aerospace standard hydraulic fittings to meet unique requirements and specifications of design engineers.